Tips to Avoid Starting Problems in Diesel Generators

Importance of Efficient Start-up in Diesel Generators

Risks Associated with Start-up Failures

Efficient start-up is essential to ensure the immediate availability of diesel generators during critical moments, such as power outages or main grid failures. Starting issues can compromise essential systems — from hospitals and data centers to industrial operations — causing financial losses and safety risks.

Start-up failures often indicate mechanical, electrical, or fuel-related problems that, if not promptly addressed, can lead to severe engine damage.

Benefits of Preventing Start-up Issues

Preventive practices reduce the number of start-up attempts, increase the starter motor's lifespan, minimize battery wear, and ensure uninterrupted power supply in emergencies. Additionally, proper maintenance and operation improve overall generator performance and reduce repair costs.

Main Causes of Diesel Generator Starting Problems

Fuel System Issues

Fuel filter clogging, air in the system, or low-quality diesel can prevent efficient combustion needed for start-up.

Technical example: Air bubbles in fuel lines lead to pressure loss, hindering proper diesel injection into the combustion chambers and causing start-up failure.

Weak or Poorly Charged Battery

The battery provides the initial energy to crank the starter motor. Discharged, sulfated, or corroded batteries are frequent causes of starting failure.

Practical tip: Regularly check battery voltage and keep terminals clean and tight.

Inefficient Ignition or Heating System

In diesel engines, pre-heating intake air is vital for ignition. Faulty glow plugs or malfunctioning temperature sensors hinder starting, especially in cold environments.

Note: In cold climates, proper maintenance of pre-heating systems is critical for reliable starts.

Practical Tips to Avoid Starting Problems

Preventive Maintenance of the Fuel System

Replace fuel filters as per the manufacturer’s schedule.

Use high-quality diesel, preferably with anti-moisture additives.

Check for air leaks in connections periodically.

Suggested procedure: Manually bleed the system after filter changes or interventions to remove trapped air.

Battery Care

Perform periodic load and capacity tests.

Inspect cables, connectors, and terminals for oxidation.

Keep the battery charger in good condition and check automatic recharge systems.

Practical example: Implement weekly inspections with a digital multimeter to track voltage and detect early degradation.

Inspection of Pre-Heating System

Regularly test glow plugs and replace them if faulty.

Check relays and sensors associated with the heating system.

In extreme cold, consider installing oil pan or coolant heaters.

Technical note: A single faulty glow plug can prevent starting in cold conditions.

Monitoring the Starter Motor and Charging System

Check starter motor for brush wear and overheating.

Test the generator’s alternator to ensure proper battery recharge.

Keeping the electrical system in good condition prevents overload and extends component life.

Safe Start-up Procedures

Follow Start-up Checklists

Before starting the generator, use a checklist that includes:

Oil and fuel level verification.

Panel indicators check (battery voltage, ambient temperature, alarms).

Visual inspection of hoses, belts, and electrical connections.

This systematic approach reduces mechanical stress and start-up failures.

Avoid Excessive Start-up Attempts

If the generator fails to start initially, avoid multiple repeated attempts without diagnosis. Repeated tries can quickly discharge the battery, damage the starter motor, and overheat components.

Recommended procedure: After two 10-second attempts with 30-second rests, stop and investigate the root cause.

Preventive Maintenance is the Key to Reliable Start-up

Efficient start-up results from strict preventive maintenance, good operating practices, and continuous monitoring of the fuel, electrical, and heating systems.

Proactively identifying failures not only prevents start-up issues but also preserves engine integrity and ensures reliable power supply in critical moments.

By adopting these practices, you invest in the safety, operational continuity, and economic efficiency of diesel-powered systems.

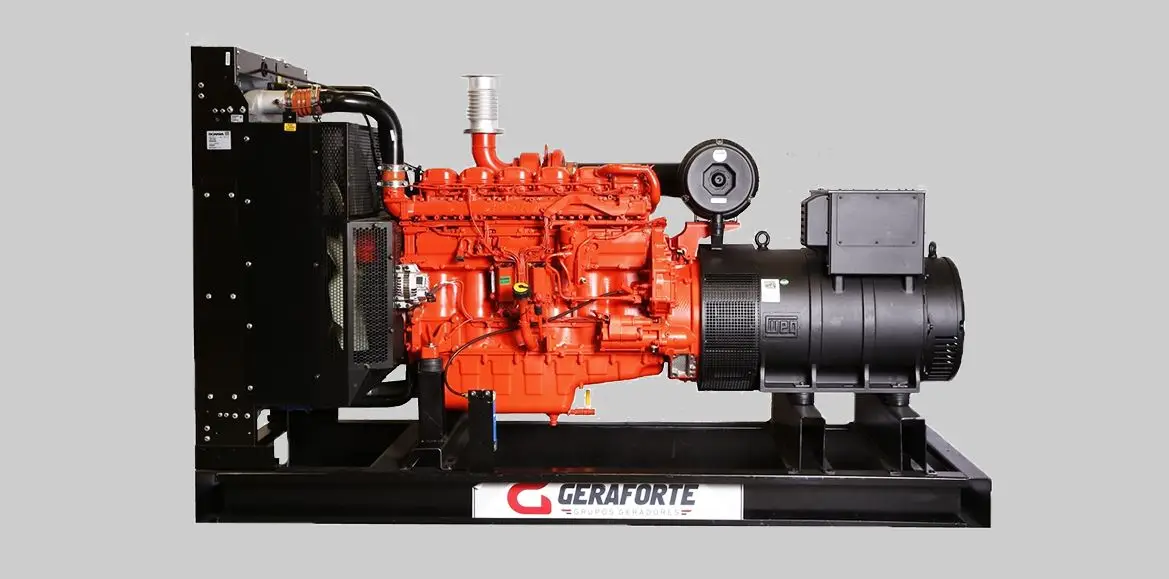

Have questions? Contact a specialized manufacturer like Geraforte, with over 16 years in the generator market. Our team of engineers and experts is ready to assist you!

Discover our products.